Key Features That Power

Your Distrubution management Experience

- Real-Time Inventory Tracking

- Order Processing Automation

- Supply Chain Visibility

- Routing and Logistics Optimization

- Warehouse Management

- Demand Forecasting

- Customer Relationship Management (CRM)

- Sales and Order Management

- Supplier Management

- Returns Management

- Performance Analytics and Reporting

- Compliance and Regulatory Management

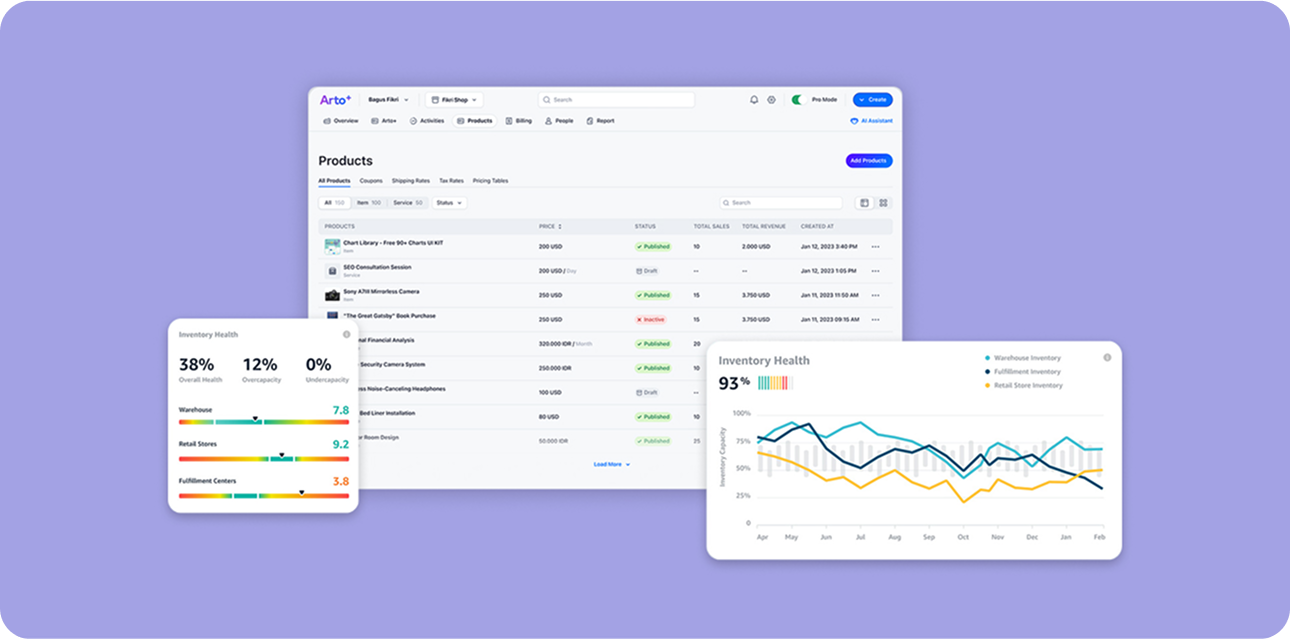

Real-Time Inventory Tracking

Real-time inventory tracking is crucial for distribution management, as it provides an up-to-date view of stock levels across multiple locations. It helps businesses monitor inventory in real time, ensuring that they can quickly respond to stock shortages or excesses. By tracking inventory levels as shipments are received or dispatched, businesses can maintain optimal stock levels, reduce stockouts, and prevent overstocking. This visibility across the supply chain enables smarter purchasing decisions, improves order accuracy, and ensures that distribution operations run smoothly with minimal delays, ultimately improving customer satisfaction and operational efficiency.

Order Processing Automation

Order processing automation streamlines the order fulfillment process, reducing the time spent on manual order entries and decreasing the chance of errors. When orders are placed, the system automatically triggers the necessary steps, including inventory allocation, invoicing, and shipment preparation. This feature integrates with other areas such as sales and inventory management to ensure that all relevant data is synchronized. Automation speeds up the order cycle, reduces operational costs, and improves customer satisfaction by ensuring orders are processed quickly and accurately. It also allows for greater scalability as the business grows.

Supply Chain Visibility

Supply chain visibility provides comprehensive insights into every stage of the distribution process. From supplier shipments to warehouse inventory and order fulfillment, businesses can track the movement of goods in real time. This transparency helps reduce delays, enhance communication between partners, and identify potential bottlenecks. With access to live data, businesses can make proactive decisions to address issues like inventory shortages or transportation delays before they affect customers. It also allows for better coordination between distribution centers, suppliers, and retailers, improving overall supply chain efficiency and reducing operational risks.

Routing and Logistics Optimization

Routing and logistics optimization is key for improving delivery efficiency and reducing transportation costs in distribution management. By using advanced algorithms, this feature helps businesses determine the most efficient delivery routes based on factors like distance, traffic conditions, and delivery time windows. This ensures timely deliveries while reducing fuel costs, delays, and the environmental impact of transportation. Routing optimization also considers the most efficient ways to load and organize shipments, improving the overall speed and cost-effectiveness of logistics. This feature is particularly valuable for businesses with multiple distribution points or extensive delivery networks.

Warehouse Management

Warehouse management in distribution helps businesses optimize the storage, movement, and tracking of inventory within warehouses. It ensures that goods are stored efficiently, picked quickly, and shipped on time. The system tracks product locations, manages stock levels, and coordinates order fulfillment to minimize delays. Warehouse management features include barcode scanning, automated stock counting, and real-time data updates, which improve accuracy and reduce manual errors. This feature helps improve warehouse productivity by optimizing space usage, reducing human error, and speeding up inventory management, ultimately enhancing overall distribution operations and ensuring timely order deliveries.

Demand Forecasting

Demand forecasting uses historical sales data, market trends, and seasonal patterns to predict future product demand. This feature helps distribution businesses anticipate inventory needs, ensuring they have enough stock to meet customer demand without overstocking. Accurate demand forecasting prevents stockouts, reduces carrying costs, and improves order fulfillment rates. By aligning procurement and production schedules with forecasted demand, businesses can optimize inventory levels and improve cash flow. Demand forecasting also enhances supplier relationships, as it enables more accurate ordering, reducing the risk of delays and ensuring that products are available when customers need them.

Customer Relationship Management (CRM)

CRM tools in distribution management help businesses track and manage customer interactions, ensuring that all orders are fulfilled according to customer expectations. The system stores detailed customer data, including order history, preferences, and purchasing behavior, enabling businesses to personalize communications and offer targeted promotions. It also tracks service levels, such as delivery times and order accuracy, allowing businesses to respond promptly to customer inquiries or complaints. By maintaining a 360-degree view of customer interactions, CRM helps businesses improve customer satisfaction, increase retention, and optimize the customer experience throughout the distribution process.

Sales and Order Management

Sales and order management helps streamline the entire order-to-delivery process. It tracks customer orders, manages quotations, processes payments, and monitors inventory levels to ensure timely fulfillment. The system integrates with inventory management to ensure that orders are only placed for items in stock and updates stock levels in real time. It also manages backorders and returns efficiently. By automating order processing, businesses can reduce errors, speed up order fulfillment, and ensure that customer expectations are met. Sales and order management also allows for better insights into sales trends and performance, driving better decision-making.

Supplier Management

Supplier management is a crucial component of distribution management, enabling businesses to track supplier performance, manage relationships, and optimize procurement processes. This feature allows businesses to evaluate supplier reliability, pricing, and delivery lead times to ensure smooth operations. By centralizing supplier data, businesses can improve purchasing decisions, negotiate better terms, and identify potential risks. The system tracks supplier orders, ensures compliance with contracts, and monitors stock levels. It also provides insights into supplier performance trends, enabling businesses to switch suppliers if necessary or work with suppliers to improve efficiency, cost-effectiveness, and delivery timelines.

Returns Management

Returns management is essential in distribution to handle product returns efficiently, maintaining customer satisfaction while minimizing costs. This feature tracks return requests, authorizes returns, and processes refunds or replacements in a timely manner. It provides transparency and helps businesses monitor patterns in returned goods, identifying issues such as defective products, incorrect deliveries, or customer dissatisfaction. The system also manages the logistics of returning goods to warehouses, including restocking or discarding items, which ensures smooth operations and accurate inventory records. Returns management enhances customer loyalty by offering easy, hassle-free return processes and minimizing operational disruptions.

Performance Analytics and Reporting

Performance analytics and reporting provide businesses with in-depth insights into their distribution operations. This feature tracks key performance indicators (KPIs) such as order fulfillment times, inventory turnover rates, transportation costs, and customer satisfaction scores. By analyzing these metrics, businesses can identify areas for improvement, optimize processes, and enhance overall efficiency. Customizable reports allow for a detailed analysis of specific functions or time periods, providing actionable insights that drive data-based decision-making. Performance analytics helps businesses track progress toward distribution goals and improve operational performance, leading to reduced costs and better service delivery.

Compliance and Regulatory Management

Compliance and regulatory management ensures that distribution operations meet industry regulations, such as safety standards, product labeling requirements, and environmental regulations. This feature helps businesses maintain documentation and records required for regulatory compliance, reducing the risk of fines or legal issues. It automates compliance tracking, ensuring that all shipments, product packaging, and delivery processes are aligned with current laws. With built-in audit trails and reporting, the system offers transparency and facilitates easy access to compliance records during inspections. By managing compliance effectively, businesses can protect their reputation, reduce risk, and streamline operations in regulated industries.